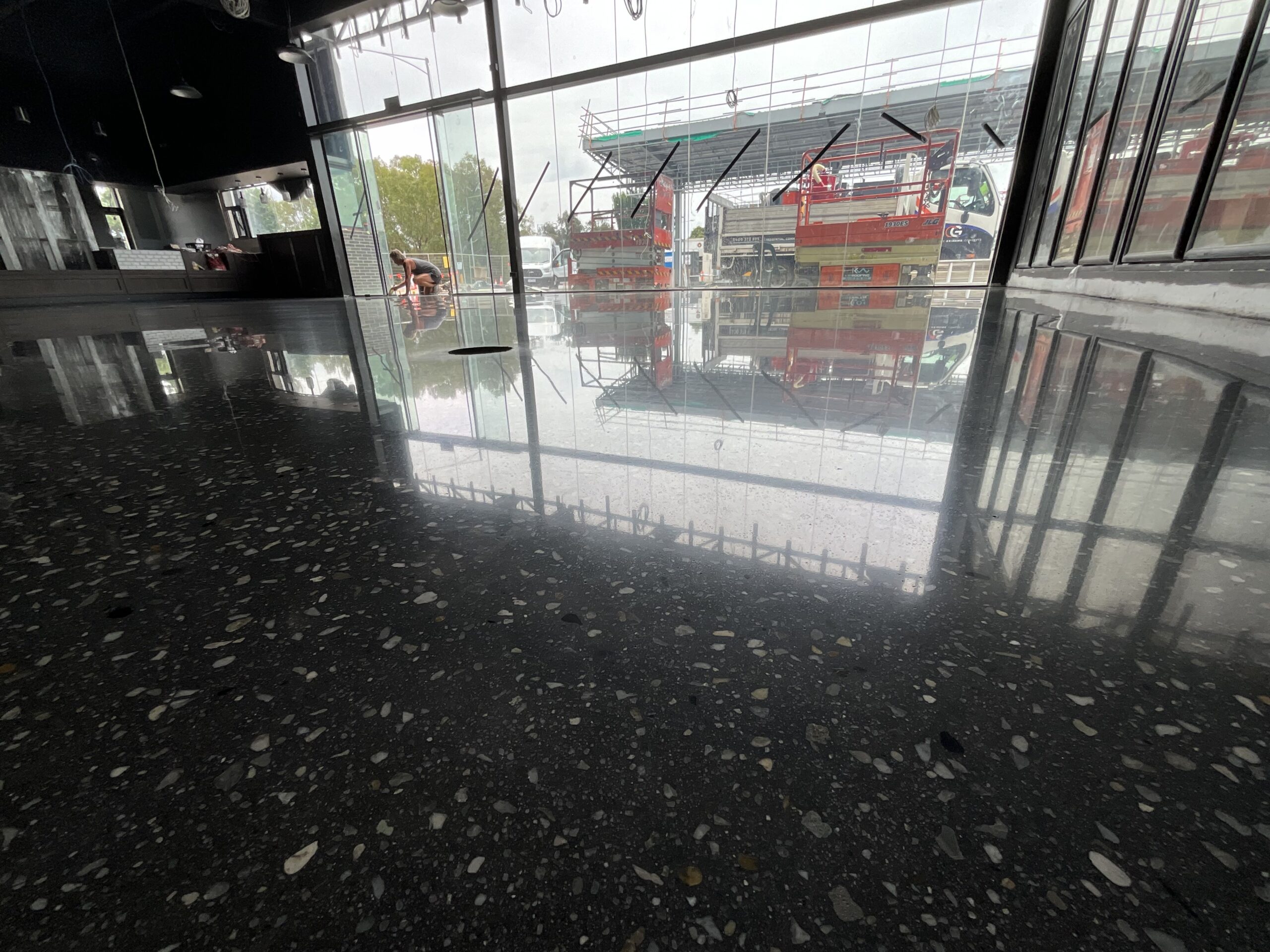

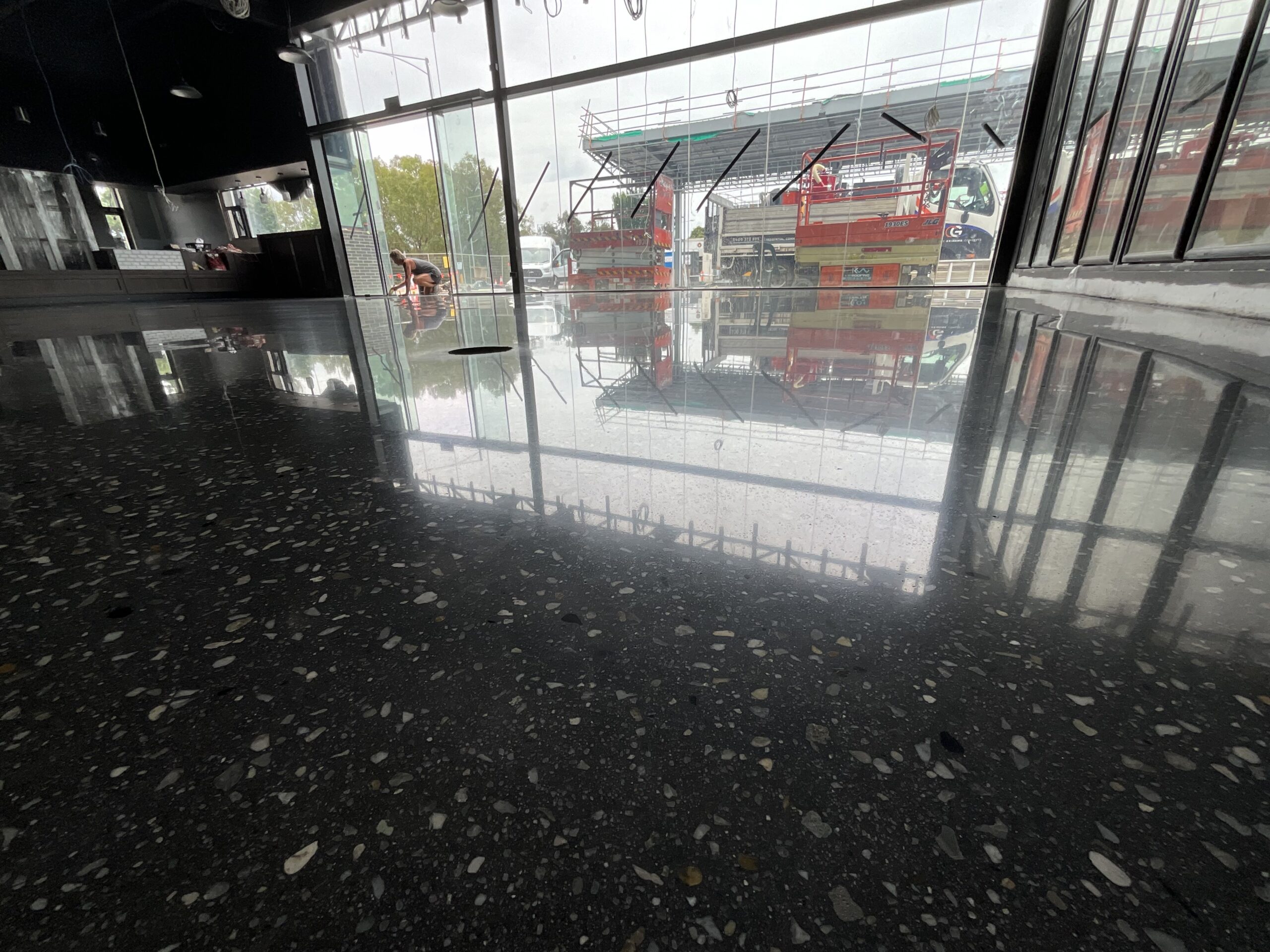

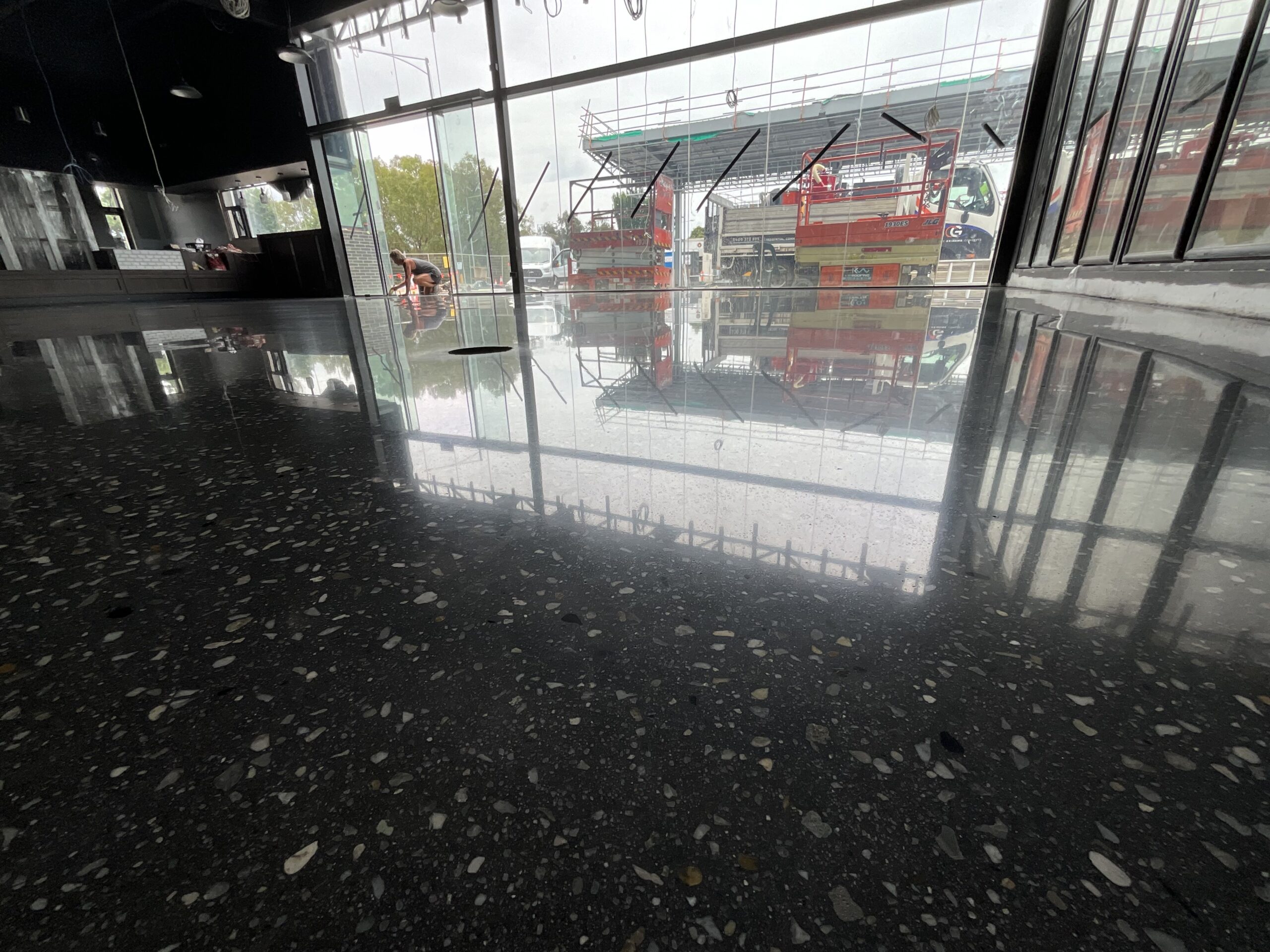

Polished concrete, also referred to as mechanical polishing, undergoes a multi-step process. Initially, we grind the floor to achieve the desired exposure level. Next, we fill majority of the holes in the concrete by grouting the floor. Following this, we apply a densifier’s to impregnate the concrete floor, enhancing its hardness and strength. Throughout this process, we continuously polish the floor using a range of different resins with different grits. Once we've sufficiently densified the floor and achieved the desired sheen, we seal it with a penetrating sealant, then buff it to finish.

Polished concrete represents a durable and luxurious finish. Unlike grind and seal methods, there's no topical coating involved. Instead, we utilize different grits in our polishing process to achieve the desired appearance, relying on the shine of the concrete itself.

Typically, concrete isn't considered polished until a 400-grit level is attained. From there, it may be further refined to 800, 1500, or even 3000 grit. This meticulous process involves approximately 12 to 14 steps depending on whether steps have to be repeated, ensuring a high-quality result.